Physical Interactive Workshops

ONSITE CERTIFIED PHYSICAL INTERACTIVE LEAN SIX SIGMA WORKSHOPS

Let’s meet and discussCertified Lean Six Sigma Yellow Belt Workshop - $395/seat

This one-day workshop provides an understanding of Lean Six Sigma principles and techniques for global excellence deployment for Industry 4.0. It introduces the basic building blocks to a Global Excellence culture with Design Innovation, Lean Six Sigma, and the Digital Thread as a three-pillar base strategy to success during the transformation to Industry 4.0.

Certified Lean Six Sigma Green Belt Boot Camp Workshop - $1,495/seat

This course is a 3-day Lean Six Sigma Green Belt Bootcamp for Industry 4.0. It focuses on fundamental Lean Six Sigma concepts and methodologies that improve and enhance the ditigal thread in manufacturing and service industries. The course introduces the participant to the digital thread, the integration of artificial intelligence (AI), advanced robotics, 3D printing, networking, cloud, cybersecurity, big data, and analytics. One of the case study examples from a Fortune 500 Medical Devices Company shows how “Value Stream Mapping,” the complete customer service digital thread helped the company modify and upgrade its software. The improved software successfully tracked approximately 6000 medical generators in an exchange program involving over 500 hospitals and medical clinics.

Each participant will learn the tools and techniques of the lean six sigma philosophy of management that focuses on eliminating defects through practices that emphasizes understanding, measuring, and improving processes. Each participant will learn how to use statistical data and equations to solve problems and improve processes.

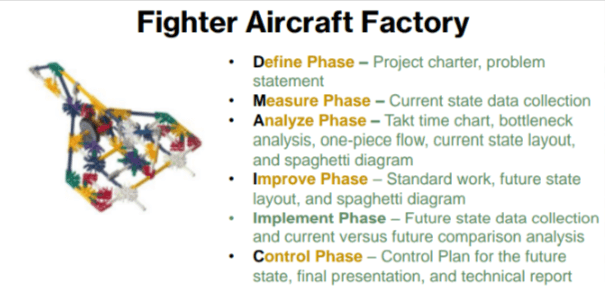

Each participant will be separated into equal teams to participate in an interactiive physical simulation fighter aircraft factory using K’Nex building blocks. Each team will be a seperate business that assembles and provides fighter aircraft to the customers based on the customer’s demands. Each team will produce fighter aircraft in their current state and utilize the DMAIC process to generate and verify their future state. This is a fun and practical method of learning Lean concepts and principles. This course will prepare professionals to be an improver of future systems in Industry 4.0.

Physical Interactive

Fighter Aircraft Factory Workshop

"People learn more from doing and having fun than from only lectures"

Certified Lean Six Sigma Black Belt Boot Camp Workshop - $2,495/seat

This course is a 5-day Lean Six Sigma Black Belt for Industry 4.0. Green Belt’s knowledge of Lean Six Sigma concepts and principles are required. The course will teach you a higher level of statistical problem solving and process improvement techniques. The course will cover all of the tools and techniques used in the Lean Six Sigma DMAIC methodology.

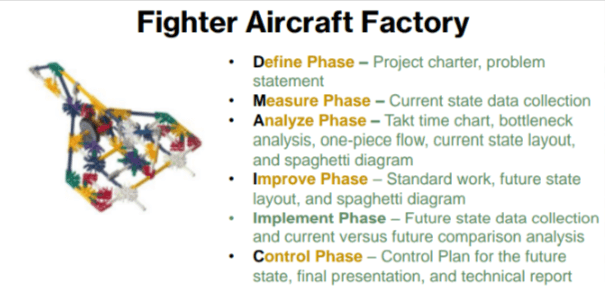

Each participant will be separated into equal teams to participate in two interactive physical simulation bootcamps called “M&M Sweet Statistics” and “Lean Six Sigma Catapult.” In the M&M Sweet Statistics bootcamp, the participant will learn and do the following:

Gage R&R Study

1 Sample T-Test

Paired T-Test

1-Proportion Test

Chi-Square Test

Linear Regression Analysis

Multiple Regression Analysis

Analysis of Variance (ANOVA)

Design of Experiments (DOE)

All of these workshops are designed to maximize the participants’ learning. They are a fun and practical method of learning Lean Six Sigma Black Belt concepts and principles. After you have learned about statistical analyses, you get to eat M&Ms. This course will prepare professionals to improve future systems in Industry 4.0.

Physical Interactive Workshops

"People learn more from doing and having fun than from only lectures"

ONSITE CERTIFIED PHYSICAL INTERACTIVE LEAN WORKSHOPS

Let’s meet and discussCertified Yellow Belt Lean Practitioner Workshop - $395/seat

This one-day Certified Yellow Belt Lean Practitioner Training-Do Workshop provides an understanding of lean principles and techniques for eliminating waste (Muda). It reinforces the White Belt leaning of a lean culture, such as built-in quality tools, the eight wastes, 5S, visual management system, flow, pull production, Kanban, standard work, and sustaining improvements. The training participants apply a Lean improvement concept or technique in their production area.

Certified Green Belt Lean Leader Boot Camp Workshop - $1,095/seat

This 2-day Certified Green Belt Lean Leader Train-Do Bootcamp prepares individuals to lead continuous improvement projects within a department or group utilizing lean concepts and principles. The training participants apply Lean improvement concepts and techniques in their production area or office during the bootcamp.

Each participant will be separated into equal teams to participate in an interactive physical simulation of a of a fighter aircraft factory using K’Nex building blocks. Each team will be a seperate business that assembles and provides fighter aircraft to the customers based on the customer’s demands. Each team will produce fighter aircraft in their current state and utilize the DMAIC process to generate and verify their future state. This is a fun and practical method of learning Lean concepts and principles. This course will prepare professionals to be an improver of future systems in Industry 4.0.

Physical Interactive

Fighter Aircraft Factory Workshop

"People learn more from doing and having fun than from only lectures"

Certified Black Belt Lean Expert Boot Camp Workshop - $1,549/seat

This 3-day Certified Black Belt Lean Expert Train-Do Bootcamp prepares individuals to lead continuous improvement projects in their plant or company enterprise utilizing lean concepts and principles. The training participants apply lean improvement concepts and techniques in their production area or office during the bootcamp.

Each participant will be separated into equal teams to participate in an interactive physical simulation M&M Sweet Statistics bootcamp.” Where the participant will learn and do the following:

Gage R&R Study

1 Sample T-Test

Paired T-Test

This workshop is designed to maximize the participants’ learning. They are a fun and practical method of learning Lean Six Sigma Black Belt concepts and principles. After you have learned about statistical analyses, you get to eat M&Ms. This course will prepare professionals to improve future systems in Industry 4.0.

Lean Black Belt Expert Physical Interactive Workshops

"People learn more from doing and having fun than from only lectures"

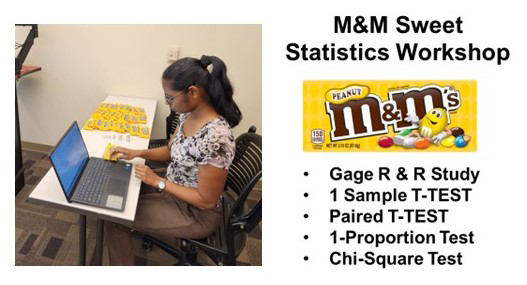

ONSITE CUSTOMIZED LEAN SIX SIGMA TRAIN-DO WORKSHOPS

Let’s meet and discussCaldwell & Associates training & coaching builds internal capabilities!

Onsite Customized Lean Six Sigma "Train-Do" Workshops

Our Customized Workshops include Certified Lean Six Sigma training and doing your company’s continuous improvement projects. Our Customized Lean Six Sigma Train-Do approach ensures the six steps of Bloom's Hierarchy of Learning, as noted above.

Certified Lean Six Sigma Train-Do Workshops

We can provide standardized or customized Lean Six Sigma Train-Do Workshops at your facilities. For our customized workshops, we tailor our classes so that your employees understand Lean Six Sigma concepts and principles by using examples from your office or plant. Caldwell & Associates Training team analyzes your office and plant operation to pull case studies for the customized training materials. It also includes information and data about how Lean Six Sigma methodologies and calculations are used to solved problems and improved processes in your plant or office. Your employees bring their Lean Six Sigma Black Belt or Green Belt Projects to analyze and discuss in class.

Brad Jones was the first to receive his Certified Lean Six Sigma White Belt at Diversified Converters Inc.