We are experts in “Dynamic Bottlenecks Solutions”

Free ConsultationDynamic bottlenecks are in most discrete manufacturing plants, and many leaders are unaware of the dynamic bottlenecks in their plants. Some leaders have never heard of the term “dynamic bottlenecks” because they are complex to solve and challenging to see in most discrete manufacturing processes. The only time dynamic bottlenecks are not in a discrete manufacturing plant is when the plant has all product lines balanced, such as automotive assembly lines, or the manufacturing plant has only one product on each process line. Therefore, most discrete manufacturing plants have dynamic bottlenecks, and management does not know what and where they are in their plant.

Do you have “Dynamic Bottlenecks” in your plant?

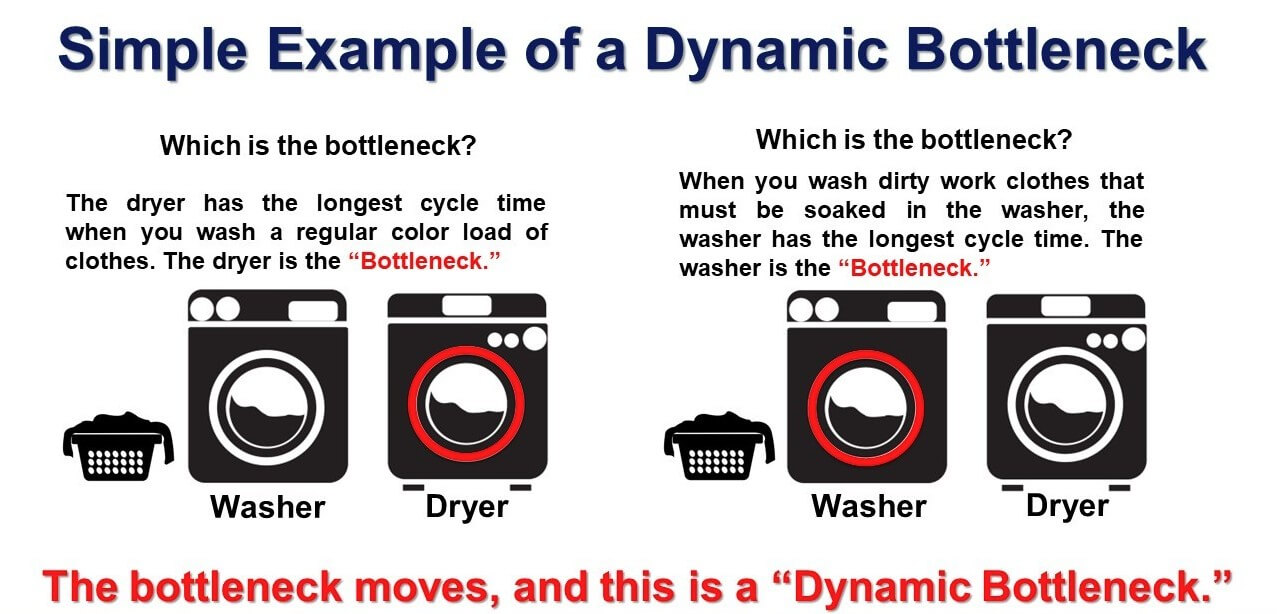

We developed the Managing Method for Dynamic Bottlenecks (MMDB) in manufacturing to increase throughput, capacity, and revenue. Let us use washing clothes as a simple example of a dynamic bottleneck. When you wash a regular load of white or colored clothes, the dryer has the longest operation time. Therefore, it is the bottleneck. However, soaking dirty work clothes in the washer is the longest-timed operation, and the bottleneck has moved to the washer, creating a dynamic bottleneck. Depending on what you wash and dry, the washer or dryer can be the bottleneck, as shown in the figure below. If you Google “dynamic bottlenecks in manufacturing,” you will find a few research papers on the subject that are so complex to read that you must have a master’s degree in engineering to understand them.

To learn more about bottlenecks in manufacturing,

watch the video below:

This video shows the problems hidden bottlenecks have in manufacturing. When you know where critical bottlenecks are in manufacturing, you can increase throughput, capacity, and revenue without adding costs. As a leader in a manufacturing plant who doesn't know where the critical bottlenecks are, you are at a disadvantage in improving throughput and capacity. Your only options are to hire more workers and buy more equipment.

Discover More

Elevate your professional skills with Caldwell & Associates' virtual Six Sigma classes, meticulously designed to transform your understanding and implementation of Lean Six Sigma principles.

Discover the path to operational mastery on our Excellence page, where we showcase the transformative successes of our past clients and the cutting-edge programs we lead

Delve into the core of Caldwell & Associates' expertise on our Lean Six Sigma page, where we detail our best practices, share inspiring success stories, and outline our program objectives.

Why don't we talk business?

Get in touch with our representatives and start your journey on expanding your company and making your business better, more agile and profitable.